2 point bend test|four point bending test setup : distributing Bending tests are performed with standardized samples and three or four pressure points (3-point, 4-point bending test). They either result in the destruction of the specimen or in its plastic deformation (only with ductile . No Reclame AQUI, empresas ruins, não recomendadas e e.

{plog:ftitle_list}

WEBMC TH. Tribo Da Periferia. Mc Neguinho do Kaxeta. Racionais MC's. Dan Lellis. Discografia. Ordenar e filtrar lançamentos. 0. 44 álbum (ns) • Ordenado por Mais .

Test Bed (or Anvils): In bend tests, the specimen is supported on two points (or anvils) on the test bed, over which the load is applied. Loading Jig (or Mandrel): The loading jig or mandrel is . The two-point bend test has been used extensively for strength and fatigue measurements of optical fiber. This paper extends the theory of 2-point bending to thin glass substrate.

ASTM E290-22. Standard Test Methods for Bend Testing of Material for Ductility. Significance and Use. 5.1 Bend tests for ductility provide a simple way to evaluate the quality of materials .In a Three-Point Bend Test, a supported sample is loaded at the center point and bent to a predetermined angle or until the test sample fractures. Failure is determined by the size and .

Bending tests are performed with standardized samples and three or four pressure points (3-point, 4-point bending test). They either result in the destruction of the specimen or in its plastic deformation (only with ductile .The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of .

The 2-point bend test is an extremely convenient technique for determining the strength and fatigue parameters of fibers in general and high strength optical fibers and ribbons in particular. First described by Murgatroyd [ref. . Two main types of bend tests i.e. 3 point bending and guided bend test are shown in the below figure. The outer portion of the bend test takes the maximum expansion by plastic deformation under tensile stresses. This .

Two-point bending (2pb) is the simplest technique for the measurement of failure strains of glass fibers under a variety of experimental conditions.

Bend tests are conducted to determine the ductility or strength of a material. This article discusses the different bend tests with emphasis on test methods, apparatuses, procedures, . 2.2. Two-point bend test. Two-point bend measurements were made using a homebuilt system, at a faceplate velocity of 50 or 4000 .The 2-point flexure test determines bending stiffness to ISO 2493-1, DIN 53121, ISO 5628 and DIN 19304, as well as the tech. quality of creasings to DIN 55437-3. . ZwickRoell's 2-point flexure test kit covers two applications: .The bend test uses a coupon that is bent in three point bending to a specified angle. The outside of the bend is extensively plastically deformed so that any defects in, or embrittlement of, the material will be revealed by the premature .

Easy to install, the 3-point fixture can be modified with an optional conversion kit to provide a 4-point bending conversion. Lower anvils are adjustable to accommodate specimens of different spans. Deflection of the specimen can be measured either through crosshead displacement, or for more precise measurement you can use a mid-span direct .

custom moisture meter winnipeg

three point vs four bending

"Bend test" and "flexure test" terms are used interchangeably in the testing industry. A bend tester is configured to your requirements by our application engineers with a three or four point bend test fixture, the correct controller, and a deflectometer if you would like to measure sample deflection directly and accurately.L, rests on two roller supports and is subject to a concentrated load P at its centre. Figure 1: Schematic of the three point bend test (top), with graphs of bending moment M , shear Q and deflection w .

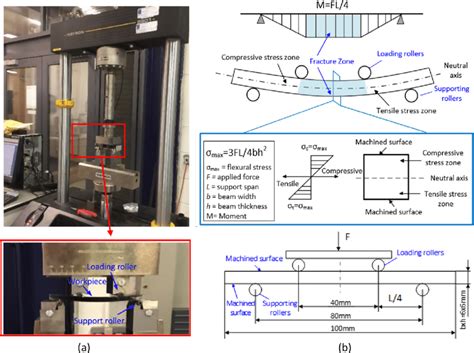

1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided bend test in which the . 1.2.5 Bending test. The three-point as well as four-point bending tests are conducted for measuring the deflection and bending strength of fiber-reinforced polymer plastics. The mechanical parameters for the bending tests lies between −269 and 600°C, .ASTM E290 A-26, ISO 7438 I-8, and JIS Z2248 J-5 are some of the general standards which describe the requirements for the bend testing of metals. In a Three-Point Bend Test, a supported sample is loaded at the center point and bent to a predetermined angle or until the test sample fractures.

In the 3-point bend test, or 3-point flexure test, to ISO 178, a bar-shaped plastic specimen is placed between two supports.; A force is then applied vertically to the top of the specimen midway between the supports. The force and the deformation of the specimen are measured to determine the flexural modulus and the flexural strength.

The three-point bend test is standardized under ASTM D790 and ISO 178, ensuring consistency and reliability in the results. A standard test method in material testing provides a uniform framework for conducting tests, enabling the comparison of results across different studies and applications. These standards outline specific procedures for .The test is the same as a 3-Point bend test and is called transverse because it's perpendicular to the beam's length. Measurements include flexural strength (or bend strength, modulus of rupture,and transverse rupture strength), stiffness and yield strength. It is commonly used to evaluate polymers, metal powders, composites and wood. A three point test is easier to perform than a four point test. The deflection measurement in three point tests is commonly measured using the machine’s crosshead position sensor (typically a digital encoder), whereas the four point bend test is commonly measured using a deflectometer. Conversion kits are available that convert a three point .

Wood and composites are most commonly tested with the 4-point bend test. The 4-point test requires a deflectometer to accurately measure specimen deflection at the center of the support span. Test results include flexural strength and flexural modulus. Brittle Materials. When a 3-point bend test is done on a brittle material like ceramic or .For corrugated board, the two-point method is not recommended. The bending according to the two-point bending method can be performed in two ways. In Figure, the beam-shaped test piece is clamped at one end and subjected to a force, 2 F, acting perpendicular to the surface of the test piece at the start of the test, at a bending length, l, from .

The two common types of bend fixtures are three-point and four-point bend fixtures: (1) Three-point bend fixtures: Configuration of flexural strength testing where a specimen is loaded at a .

σ = 3 F L 2 b d 2. for a three-point bending test, where: F is the maximum load applied (N) L is the support span length (mm) b is the width of the specimen (mm) d is the depth of the specimen (mm) Flexural Modulus (Modulus of Elasticity) .The flexural test on concrete can be conducted using either three point load test (ASTM C78) or center point load test (ASTM C293). The configuration of each test is shown in Figure-2 and Figure-3, respectively. Test method described in this article is according to ASTM C78. Fig.2: Three-Point Load Test (ASTM C78)

four point bending test setup

The two-point bend test has been used extensively for optical fiber strength and fatigue measurements. This paper extends the theory of 2-point bending to thin glass substrates. The key advantages of the 2-point bend test are 1) the simplicity of a test fixture and its operation, 2) the uniformity of a bend stress along the width of a substrate . Bend tests are commonly performed on metals, plastics, and composites. The most common type of bend test is the three-point bend test, which is used to measure the flexural strength of materials. In this test, two supports are placed on either side of the specimen, and a force is applied to the middle of the specimen.Wood and composites are most commonly tested with the 4-point bend test. The 4-point test requires a deflectometer to accurately measure specimen deflection at the center of the support span. Test results include flexural strength and flexural modulus. Brittle Materials. When a 3-point bend test is done on a brittle material like ceramic or .

The 3-point flexure test to ASTM D790 is a traditional standardized characterization method for rigid and semi-rigid plastics. The flexural properties determined with these tests are of great importance to designers, engineers and material manufacturers to ensure that the plastic material used meets the requirements for its intended application.In the 2-point flexure test, the specimen is gripped at one end and loaded with a test die on the exposed side.. The 2-point flexure test kit is suitable for testing paper, cardboard, and films. It is used to determine the bending stiffness (using the beam method) and bending resistance of paper, board, and cardboard, e.g. to DIN 53121, ISO 5628 and DIN 19304, plastic films for .A three-point bend test applies force at the midpoint of a rectangular specimen, which is freely supported at either end. The applied force is measured by a load cell, and the resulting deflection is measured by either the system’s crosshead displacement (with results corrected for system compliance) or by a direct strain measurement device . Jenis-jenis Uji Bending. Pengujian bending memilikidua jenis atau cara pengujian, diantaranya : Pengujian Dua Titik (Three-Point Bending): Metode ini merupakan salah satu metode yang paling umum digunakan dalam uji bending. Pada uji ini, beban dipasangkan pada bagian tengah sampel bahan, sedangkan dua titik dukungan berada di kedua ujungnya.

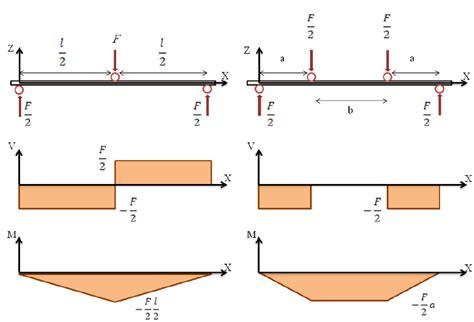

Flexural stress at break: The flexural stress at which a specimen breaks during a bend test. For some materials, the specimen breaks before a yield point, in which case the flexural strength equals the flexural stress at break. Test Method. ASTM D790 describes two different test procedures intended for different types of material.2.2. Four point bending test (4PBT) Another test utilized in the investigation of fracture in concrete specimens is the four-point bending test (4pbt), whose setup can be seen in Fig. 2.8 which is very similar to the 3pbt beams, except that two halved forces (F/2) are applied at a certain distance on both sides of the notch, rather than being .

custom moisture meter with alarm

A probabilidade de vencer em cada concurso varia de acordo com o número de dezenas jogadas e do tipo de aposta realizada. Para a aposta simples, com . Ver mais

2 point bend test|four point bending test setup